Water level - capacitive (Trutrack)

Parameter to be measured:

water level and temperature

Method:

capacitive

Equipment:

TruTrack WT-HR xxxxx

Advantages:

- Cheap

- Easy to install

- Optional Logging of battery level, water and air temperature in 8 / 12 bit resolution

- Logging of 64 k of data

- Logger start by starting condition or start time

Disadvantages:

- Water level measurement is temperature sensitive. The internal temperature compensation does a unreliable job: (stronger) temperature changes MAY produce periods (up to 60 min) of very noisy data.

- Internal Logger calibration: The loggers can be calibrated for exact water level measurements. The loggers may loose this internal calibration for no apparent reason, producing raw data instead. If independent readings are available, the record may be saved by "post-calibration".

- No outside sign of logger operation: For checking the proper logger operation, you must connect a computer to the logger. A full/not activated/malfunctioning logger cannot be detected otherwise.

- Logger connects via serial port: For most modern laptops you will need a USB to Serial(RS232) adaptor, causing yet other problems (sic). Newer shipments come with a custom cable cable with an built-in USB-serial converter.

- Bugs in Logger-Software (OmniLog): The detection of the connected loggers is unstable. Detection may fail for no apparent reasons. Reinstalling the software may help. Another reason may be the slightly reduced voltage at laptop ports being insufficient for communication with the logger. Try a desktop computer. Bringing the loggers inside for a couple of hours/days may also help.

- If any of your records happen to coincide with midnight exactly, the data export to Excel will produce faulty date values for these records, i.e. for 5-min resolution 2013-01-01 00:00 follows 2013-01-01 23:55.

- Poor (=nonexistent) customer support: No problem-related reply of the manufacturer whatsoever has ever been reported. You will, however, get a quick answer if you make an inquiry about an item you'd like to order.

What to watch out for:

- Make sure the inner rod is screwed tightly into the logger-unit. To check that you need to unscrew the metal casing from the logger-unit. Shaking during transport might also loosen this connection.

- The internal clock of the logger automatically synchronizes with the system time when the logger is connected to a PC. This may be undesirable, especially with daylight saving issues.

- The COM-port autoseek option is unreliable. Better choose the port manually.

- If you repeat the calibration of water height within a few minutes, the result may be slightly affected by drops still clinging to the inner tube. If you expect rapid drops of water level, it makes sense to include this effect, otherwise dry the tube before calibration.

- The *.dbf-files after download can be opened with a standard spreadsheet software. However, the date-column is different, so better use Omnilog for conversion/export.

Problems/Questions:

EC could influence the signal (Larson and Runyan, 2009)

Changing the battery:

Depending on logger use, the internal battery may last several years. It is not intented to be replaced by customers, so if empty, the logger has to be returned. On request, the manufacturer provides replacement battery packs (~25 €) and instructions how to change them (steps 1-3; 8-10). Alternatively, the battery may be purchased separately and replaced (steps 4-7), taking ~20 min in total. The battery is a 1/2 AA Lithium 3.6 V with soldering tags (~ 5 €). Cheaper 3 V lithium batteries of the same size exist and MAY work, but are not worth the trouble of getting through this:

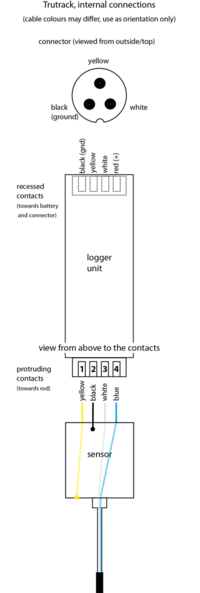

- 1. For easier handling, detach logger/sensor unit from outer rod by unscrewing it at the small seam between the topmost venting hole and the sticker - this should be possible with bare hands. Unscrew the inner rod; withdraw and coil white cable (temperature sensor).

- 2. Detach the battery pack (top 5 cm) from the logger (rest): Unscrew at the seam that is covered by the top of the sticker. This requires brute force, but do not deform the stainless steel casing. Padding a vise with pre-shaped pieces of wood works well. Opening should reveal a red, white, yellow and black cable (from left to right, looking onto the circuit board, sensor cable facing away. If you find different colours, you opened at the wrong seam. Re-close following step 10.).

- 3. De-solder cables from circuit board. Prevent the red cable touching the black one or the casing, as this short-circuits the (old) battery.

- 4. Remove screw-on cap covering connection jack. Remove rubber ring to protect it from damage. Screw on cover cap tightly with a pair of pliers. This should draw the jack out of the stainless-steel tube. Carefully draw the jack out as far as the cables permit.

- 5. The battery is glued into the tube with some blackish silicon stuff. You can push the battery out from the threaded end of the tube towards the now freed jack.

- 6. De-solder the old battery and replace with new one. The black cable must be connected to minus of the battery AND a pin of the jack. Beware: the Lithium battery is very sensitive to heat. If the new battery has no soldering tags, roughen the contacts with sandpaper and put the battery in the freezer to cool it down before soldering swiftly.

- 7. Cover the red cable with some tape to prevent short-circuiting. Insert soldered-on battery (+ first), jack and cables into steel tube from non-threaded side. Before settling the jack back in place, fill the space between the battery bottom and jack-contacts with silicon. Set the jack back into the tube (may need a tap with a hammer - use cover cap to protect the thread), glueing it with Loctite or similar. Warning: If you intend to hang the Trutrack from the screwed-on cap, this attachment is crucial. Push rubber ring over the jack.

- 8. Solder red, white, yellow and black cable back of the renewed battery pack to circuit board (see 2.). Check for solder bridges between contacts.

- 9. Connect the logger to computer and verify proper function. If OK, disconnect.

- 10. Pre-twist the battery pack 1 1/2 turns counter-clockwise before screwing it to the logger. Apply Loctite to the thread before closing the gap.

- 11. Repeat 9. before the sealant has dried.

- 12. Undo step 1. by inserting the sensor cable into the inner rod; screw the logger into the inner, then the outer rod (stainless steel tube).

Recovering data:

Data may still be retrieved from the logger after the battery dies: Change battery as described above. Connect logger and click "Tools" -> "General toolbox" -> "Read a reset logger". The data may then be handled as usual, probably accompanied by some memory trash.

Price:

between 230 and 300 EURO (2011, Germany) depending on the length

Links

Projects that used the above equipment:

Other related web sites:

References

add references here...